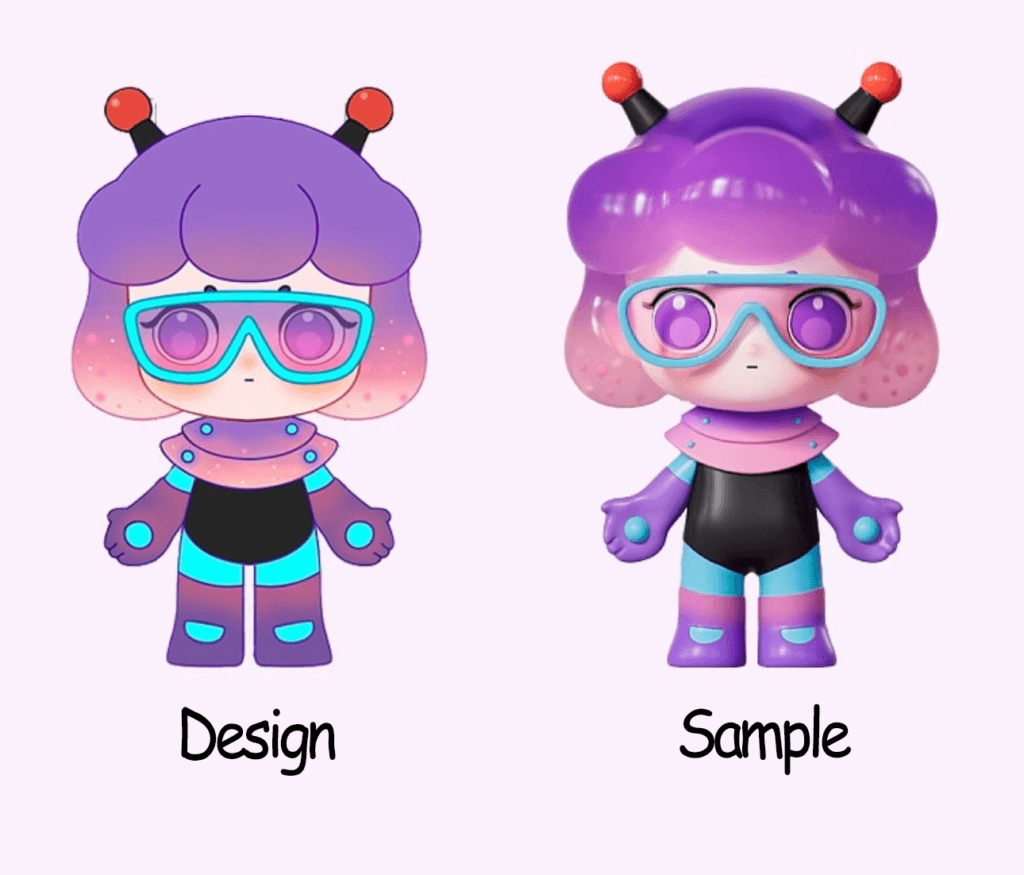

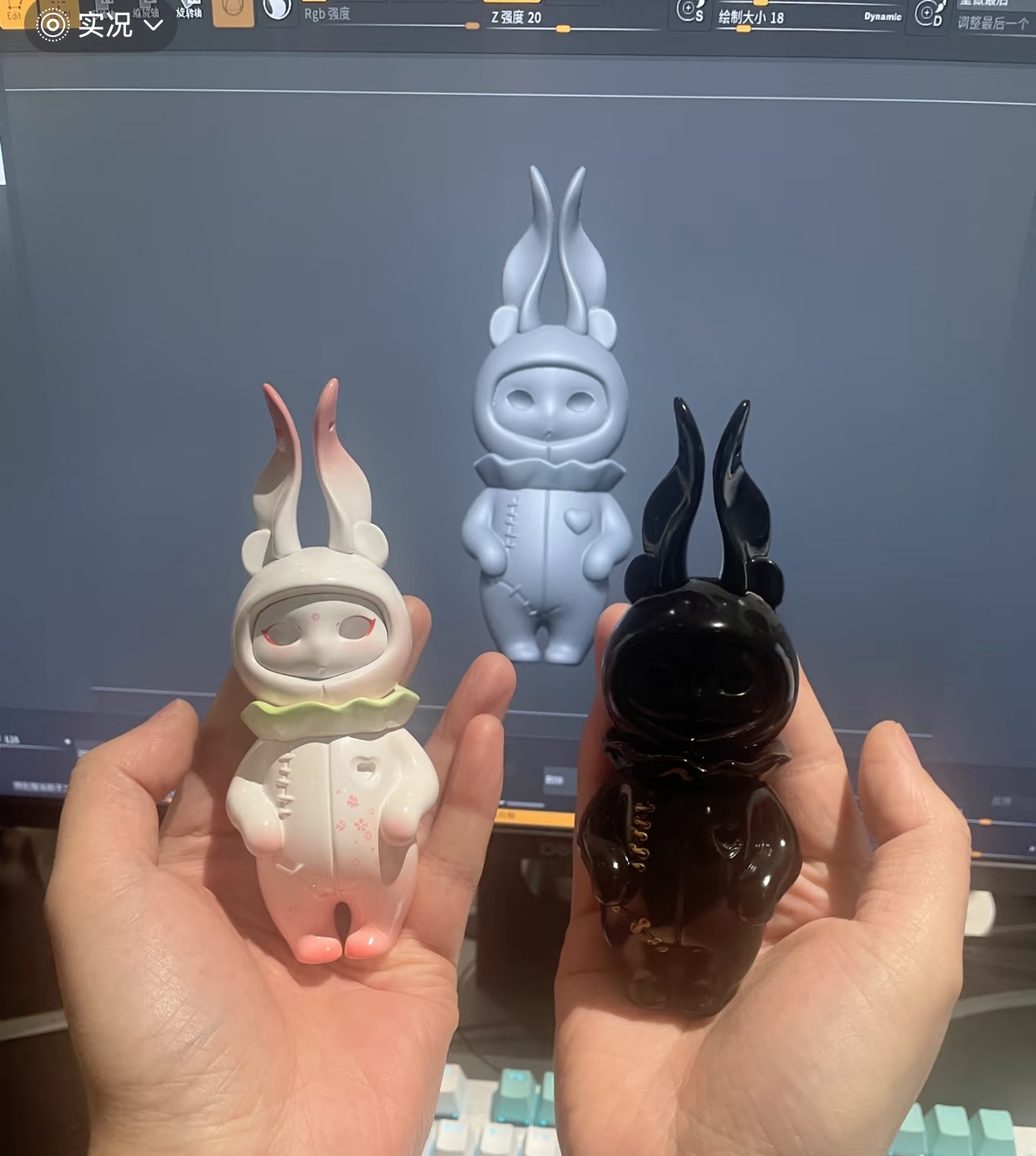

How To Make A Resin Figure?

To make a resin figure, begin by conceptualizing and designing your figure, create a prototype, make a silicone mold, cast the resin, and finally, demold and finish your piece. By following these steps, you can craft a unique resin figure that showcases your artistic vision.