Comment les jouets en vinyle personnalisés révolutionnent le marché des objets de collection?

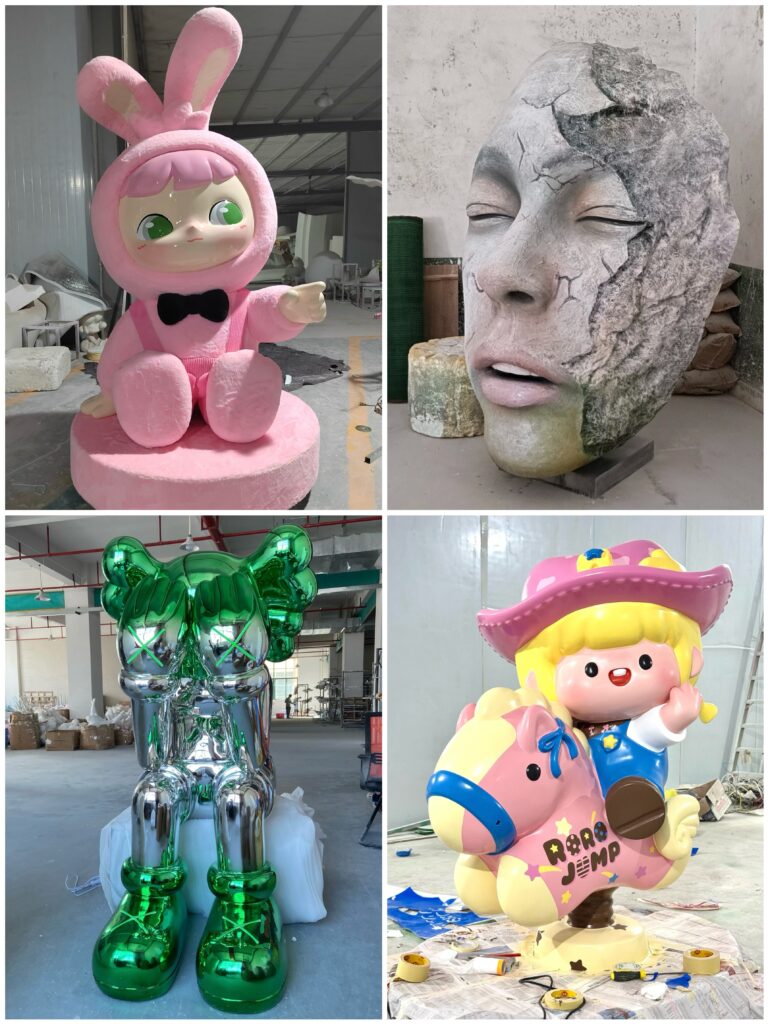

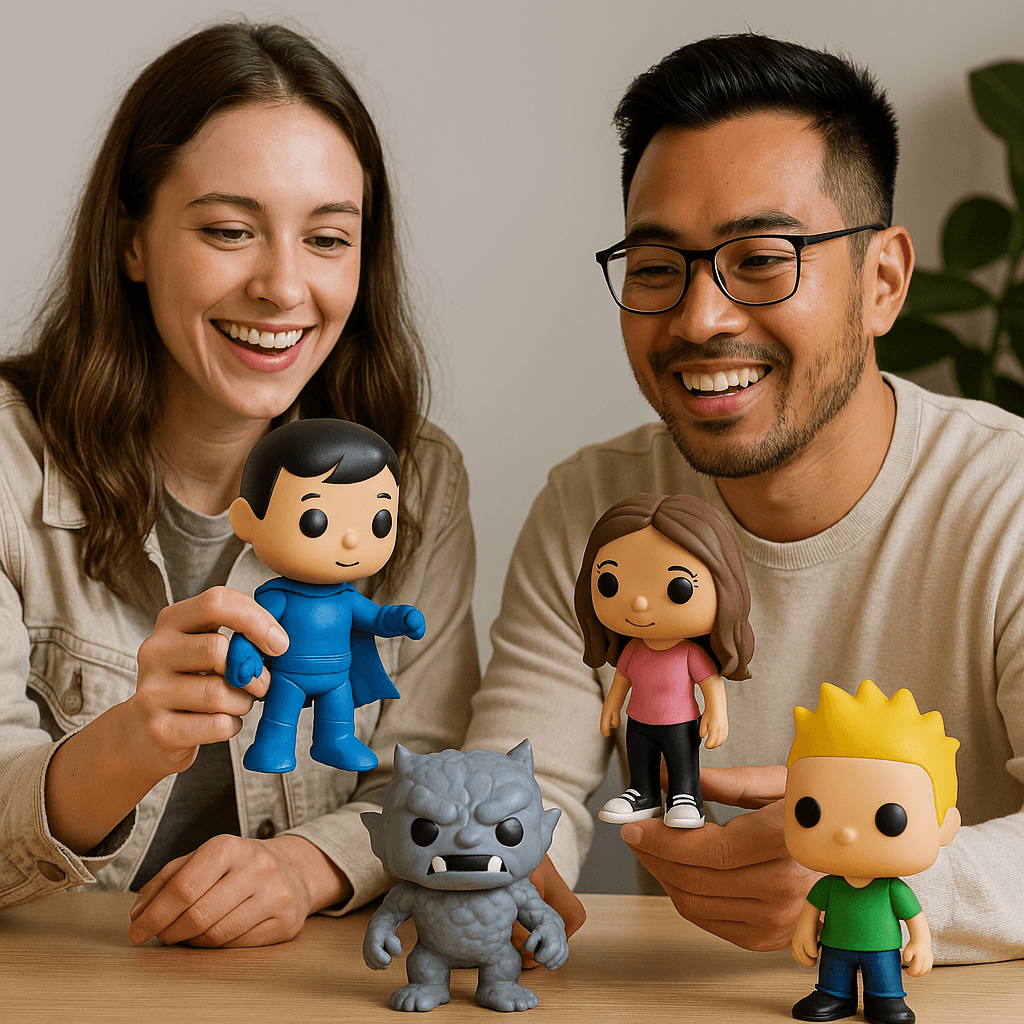

Les jouets en vinyle personnalisés révolutionnent le marché des objets de collection en offrant des produits personnalisés de haute qualité. Cet article explore leur popularité croissante, leur impact sur les marchés mondiaux et la manière dont notre société peut vous aider à créer les figurines personnalisées parfaites pour votre collection ou votre marque.