How Do You Turn an Original Character into a Collectible Toy?

This guide shows how to create original character figures from concept to product—covering sculpting, materials, and timelines for custom figurine production.

أتمنى أن تستمتع بقراءة منشور المدونة هذا. إذا كنت تبحث عن ألعاب راتنج مخصصة, انقر هنا.

يمكن أن تتعثر الأفكار العظيمة عندما يطالب المعجبون المتعطشون للتفاصيل بالكمال. المواعيد النهائية الفائتة والمواصفات المشوشة تضر بالزخم. اتبع خارطة الطريق هذه لتحويل الأحلام الهشة إلى ألعاب فنية من الراتنج المرغوبة - دون صداع.

يرشدك هذا الدليل إلى كل خطوة - اختيار المواد، والنحت الرقمي، وصب السيليكون، والطلاء الحرفي، والتغليف الواقي، والشحن العالمي. ستتعرف على الجداول الزمنية ومحفزات التكلفة والحيل الاحترافية التي تحافظ على الجودة العالية مع الحفاظ على الكميات منخفضة، مما يجعل كل لعبة راتنج مخصصة جديرة بالعرض وإعادة البيع.

دعنا نتتبع الرحلة من لوحة الرسم الفارغة إلى قطعة عرض لامعة - مرحلة عملية في كل مرة.

يبحث هواة جمع التحف عن الثقل والتفاصيل الدقيقة؛ والراتنج يوفر كلا الأمرين. على عكس المواد البلاستيكية الأكثر نعومة، فهو يحتفظ بتفاصيل دقيقة ووزن مبهج يشير على الفور إلى القيمة الممتازة.

يعالج البوليمر الكثيف من الراتنج في درجة حرارة الغرفة، ويلتقط القوالب الدقيقة التي لا يستطيع القالب الفولاذي التقاطها. يحافظ معدل انكماشه المنخفض على سلامة الأنوف وخطوط الفرو والمسامير الدقيقة - وهو مثالي للدفعات الصغيرة التي تقل عن 500 قطعة.

بينما يتألق الـ PVC في عمليات التشغيل الكبيرة والمرونة الآمنة للأطفال، فإن الراتنج يجذب جمهور البالغين الذين يعرضون بدلاً من اللعب. كما أن ملمسه الرائع الشبيه بالحجر يُضفي شعوراً بأنه من فئة المتاحف، ويحب الرسامون قاعدته البيضاء الحقيقية التي تتقبل الأصباغ بشكل نظيف. الجوانب السلبية؟ الهشاشة والصب اليدوي. ومع ذلك، بالنسبة للعلامات التجارية التي تبحث عن هالة فاخرة - الاتفاقيات الحصرية المحدودة، وتماثيل Kickstarter، وتماثيل معرض الصور - يظل الراتينج الخيار الذي لا مثيل له.

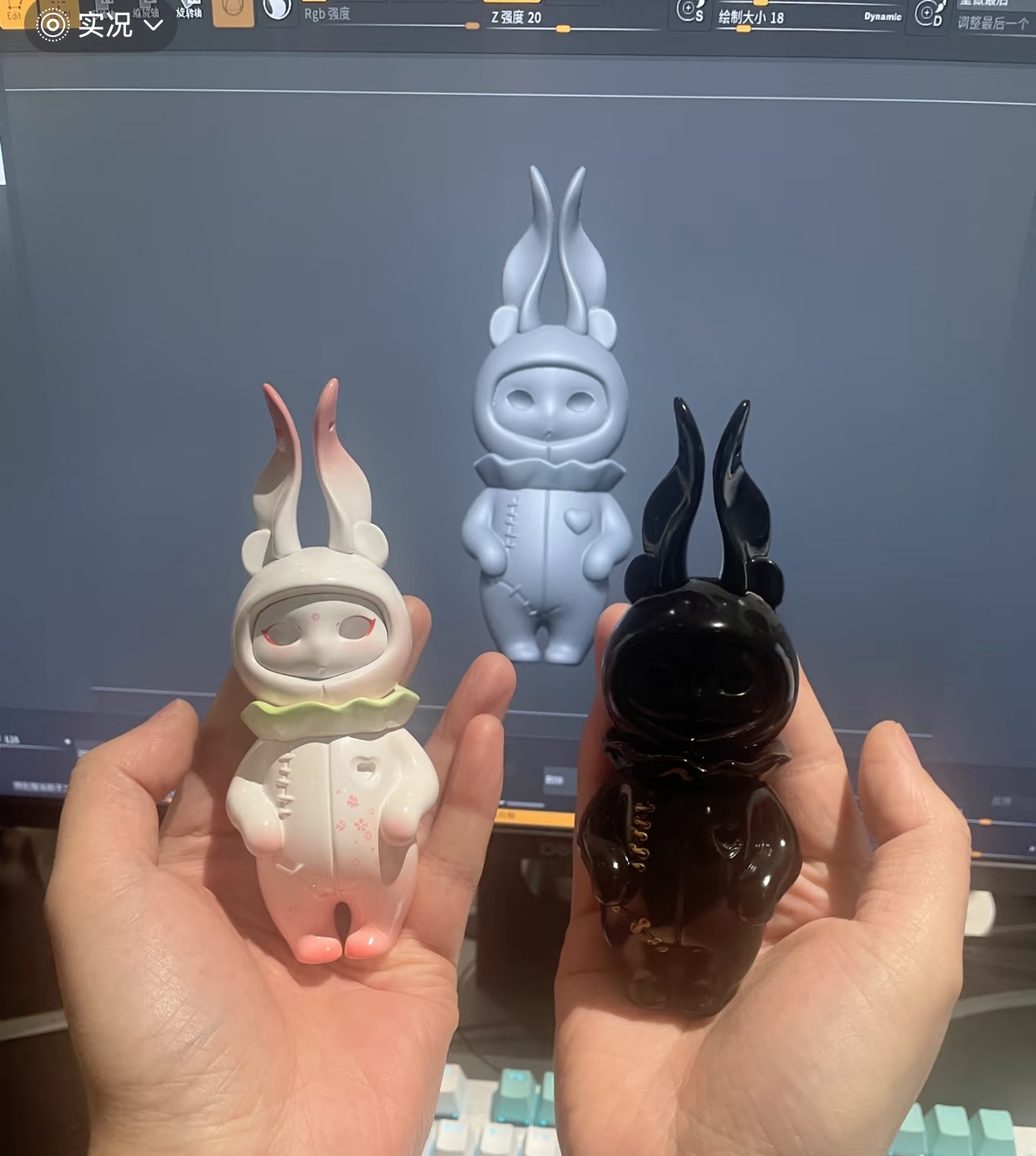

يبدأ كل بطل رف من أبطال الرفوف كرسمة فضفاضة. ومن هناك، يضغط الفنانون على النسب في ZBrush، ويقطعون المفاصل والمفاتيح حتى تنجو الوضعية من الجاذبية وصدمات الشحن.

قم بتصدير ملفات STL أو OBJ محكمة الإغلاق، وحافظ على سُمك الجدار أعلى من 3 مم، وقم بتسمية الأجزاء المنفصلة بوضوح. هذه العادات تمنع "الجزيرة غير المدعومة" المخيفة التي تطارد قوالب السيليكون.

ابدأ باختبارات الصور الظلية: قم بإسقاط نموذجك الرمادي على خلفية سوداء نقية وتحقق مما إذا كان المخطط لا يزال يبدو مبدعًا عند تقليصه إلى حجم صورة مصغرة على Instagram. بعد ذلك، قم بتشغيل طبعة ثلاثية الأبعاد - حتى نموذج أولي تقريبي FDM - لتأكيد التوازن. أخيرًا، أضف أوتاد التسجيل والفتحات في البرنامج؛ القيام بذلك رقميًا يوفر ساعات من ترقيع الطين على النماذج المطبوعة.

يتم تنظيف المطبوعات الرئيسية وتجهيزها وتعبئتها داخل إطارات خشبية. يسكب السيليكون السائل فوقها ويلتقط كل رمش في سالب مطاطي.

وبمجرد أن يعالج السيليكون، يقوم الحرفيون بقطع قنوات التدفق، ثم يخلطون يدوياً راتنج البولي يوريثان المكون من جزأين، ويصبغونه إذا لزم الأمر، ثم يقومون بصبّه بالضغط لإزالة الفقاعات. يعالج خلال 30-45 دقيقة.

وينتج كل قالب ما يقرب من 25-40 عملية سحب مثالية قبل أن ينهار السطح؛ وقد تؤدي القرون أو الأجنحة المعقدة إلى خفض ذلك إلى النصف. يقوم المنتجون الأذكياء بترتيب القوالب المتعددة وتناوبها للحفاظ على ثبات الإنتاج. بعد إزالة القوالب، يتم تشذيب الدرزات باستخدام شفرات المشرط، ويتم ترقيع الثقوب الصغيرة باستخدام معجون البقع. يكشف انفجار سريع للسطح الرمادي عن العيوب العنيدة لإعادة الصقل - وهو أمر حاسم قبل أن يلامس أي طلاء البلاستيك.

يبث اللون الحياة في الأشكال الثابتة. طبقة أولية خالية من العيوب تمهد الطريق؛ فالأخطاء هنا تطارد كل طبقة لاحقة.

يقوم الفنانون باستخدام البخاخة بالألوان الأساسية، ويضعون قناعًا بشريط لاصق للحصول على حواف حادة، ويضعون تفاصيل يدوية للعيون أو التدرجات أو التجوية. وأخيرًا، يتم استخدام الطلاء الشفاف غير اللامع أو اللامع لتثبيت الأصباغ وإضافة عمق ملموس.

تقوم العديد من الاستوديوهات بتشغيل أكشاك رش صغيرة مزودة بفلتر أسفل السحب لإبعاد الغبار عن الطلاء الرطب. تتطلب المعادن طلاءً أسود لامعًا تحت الطلاء؛ بينما تتوهج اللآلئ أكثر لمعانًا على اللون الأبيض. تعالج الملصقات أو الشعارات ذات الشرائح المائية طوال الليل، ثم يتم طلاؤها بطبقة نهائية مقاومة للأشعة فوق البنفسجية. بالنسبة للإصدارات الفاخرة، يضيف المصممون طلاءً متجمّعًا أو طلاءً كهربائيًا بالكروم أو طلاءً ناعم الملمس، مما يزيد من السعر ولكن أيضًا من الندرة المتصورة.

لا شيء يقتل النية الحسنة أسرع من القرون المحطمة. فيزياء الرغوة مهمة بقدر براعة النحت.

استخدم حشوات مخصصة من EVA أو EPE، بسمك لا يقل عن 25 مم حول النتوءات. يجب ألا تقل قوة انفجار الكراتين الخارجية عن 200 رطل، وأن تكون مزدوجة الجدار للشحن البحري.

أضف داخل الصندوق، أضف هلام السيليكا لمحاربة الرطوبة وبطاقة شكر تحمل علامة تجارية لرفع مستوى فتح العلبة. ضع علامة "FRAGILE-RESIN TOYS" على العلب الكرتونية بلغتين؛ حيث يستجيب مناولي الشحن بشكل أفضل عندما تصرخ الملصقات. بالنسبة للقطرات الخاصة بكبار الشخصيات، تُشحن التماثيل المصنوعة من البولي راتينج في طبقات من الصدف بالإضافة إلى الأكمام الفنية، محشوة برغوة مقطوعة بالقالب. ضع في اعتبارك التأمين: تغطي شركتا UPS وFedEx ما يصل إلى $100 الأمريكية بالتقصير - وهو ما يكفي لـ $300 الأمريكية للقطعة الفنية. توسط في التغطية الإضافية أو رتب شروط DDP إذا كان المشترون لا يحبون الأوراق الجمركية.

من أول خربشة في كراسة الرسم إلى اللحظة التي ينشر فيها أحد هواة جمع التحف بكرة فتح العلبة، تأخذ كل لعبة راتنج مخصصة مساراً مدروساً بعناية. يتوقف النجاح على الملفات الصلبة، وقوالب السيليكون النظيفة، والصنفرة الصبورة، وفناني الطلاء الذين يفهمون الضوء وكذلك اللون. أضف إلى ذلك التتبع الذكي للتكاليف، والرغوة المصنوعة من الرغوة التي تستخدم في المتاحف، وشريك شحن تثق به، وستحصل على غرض يحمل قيمة عاطفية ونقدية على حد سواء. إذا كنت مستعداً لرؤية شخصياتك مصبوبة من الراتنج الذي لا تشوبه شائبة - وتوصيلها إلى جميع أنحاء العالم دون أي تشقق في الأذن - فقم بإرسال خط على معلومات@customarttoy.com أو قم بزيارة customarttoy.com. سوف تتولى DesignaToy الدقة؛ وتحتفظ أنت بالأضواء الإبداعية.

أنا أستمتع حقاً بصناعة الألعاب الفنية لأن عملي يجعل منتجات عملائي أكثر جمالاً ومتعة. إذا كانت لديك أي أسئلة حول ألعاب الراتنج المخصصة، فلا تتردد في الاتصال بي!

This guide shows how to create original character figures from concept to product—covering sculpting, materials, and timelines for custom figurine production.

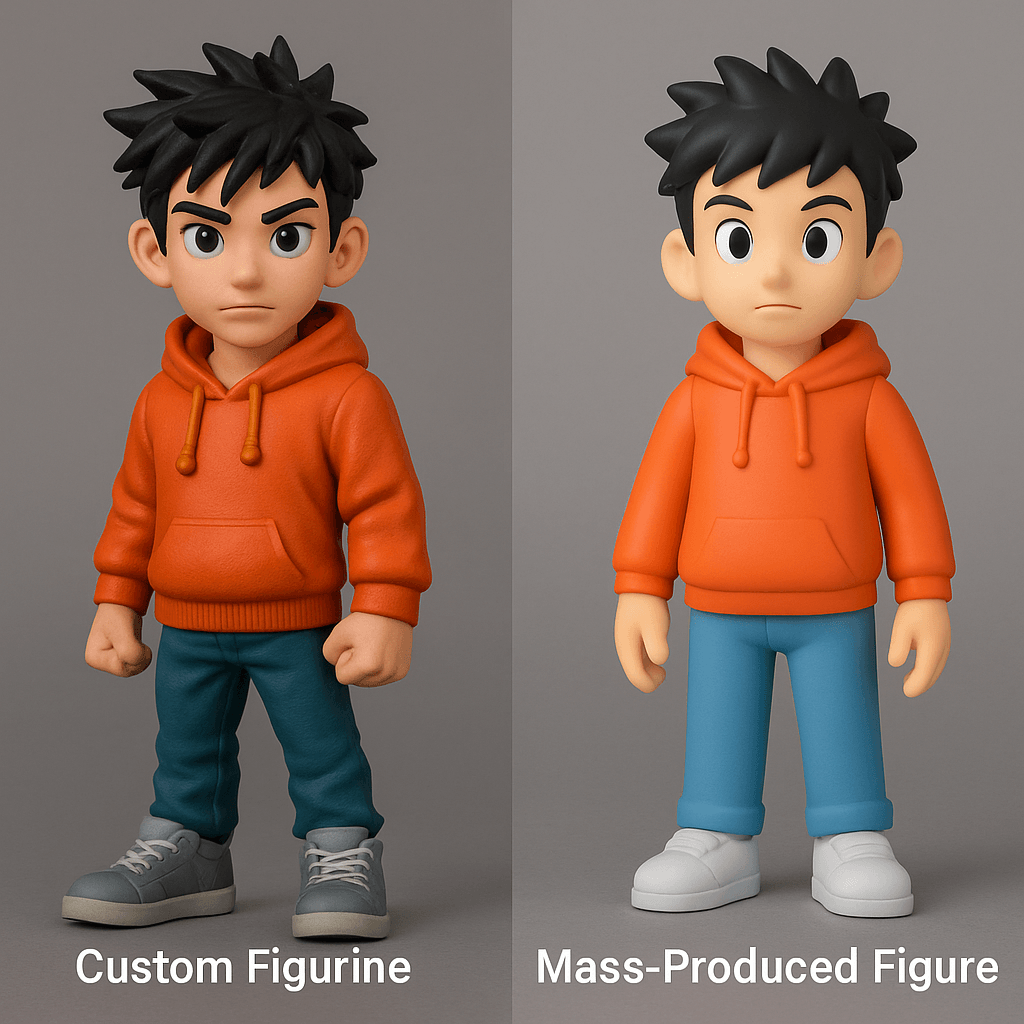

تعرّف على الاختلافات الحقيقية بين التماثيل المخصصة والمجسمات المنتجة بكميات كبيرة - بدءًا من التكلفة والجودة وحتى الجدول الزمني والعلامة التجارية. تساعدك هذه المقالة على اختيار المسار الصحيح لمشروع لعبتك.

يكشف هذا الدليل عن سير العمل الكامل للألعاب المصنوعة من الفينيل المخصصة، بدءًا من التصميم الفني إلى الشحن العالمي، ويغطي مواصفات التصميم وخيارات التشكيل والتعاون مع المصنع والتحكم في التكلفة وأساليب الإطلاق التي أثبتت جدواها لزيادة المبيعات إلى أقصى حد.

نحن شركة تصنيع ألعاب فينيل مخصصة مخصصة لتحويل أفكارك الإبداعية إلى شخصيات فريدة وعالية الجودة. مع التركيز على التفاصيل والتخصيص، نحقق رؤاك، سواء لمشاريع شخصية أو مجموعات إصدار محدود.

هل تحتاج إلى المساعدة في أمر ما في وقت قصير؟ لدينا خطة تناسبك.